News

Charities we supported in 2025

We proudly helped 11 inspiring charities in 2025.

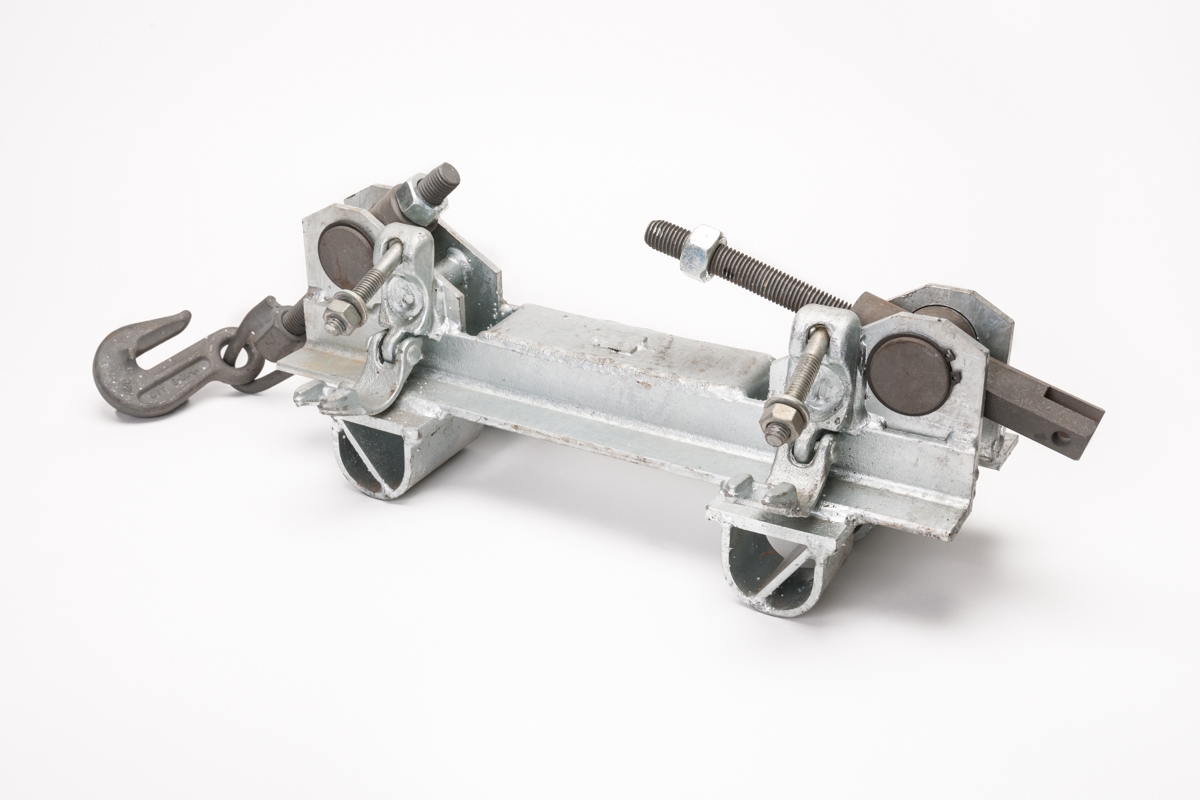

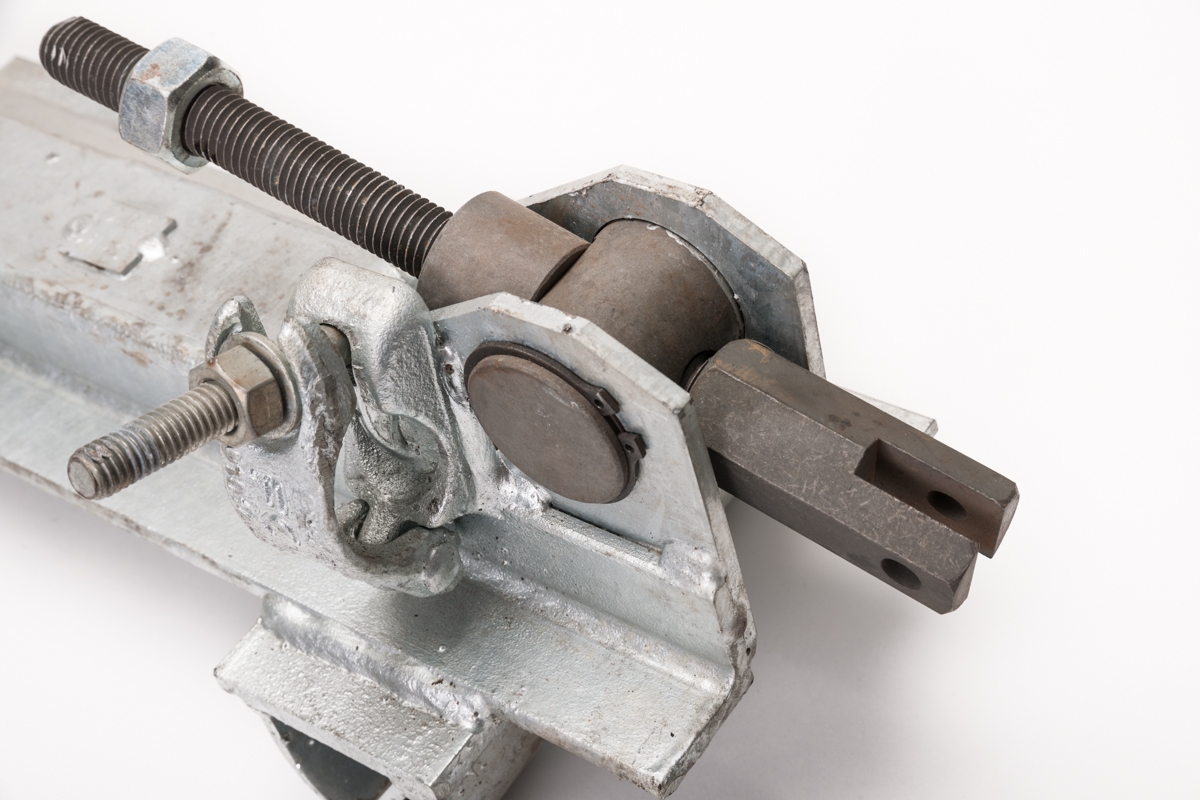

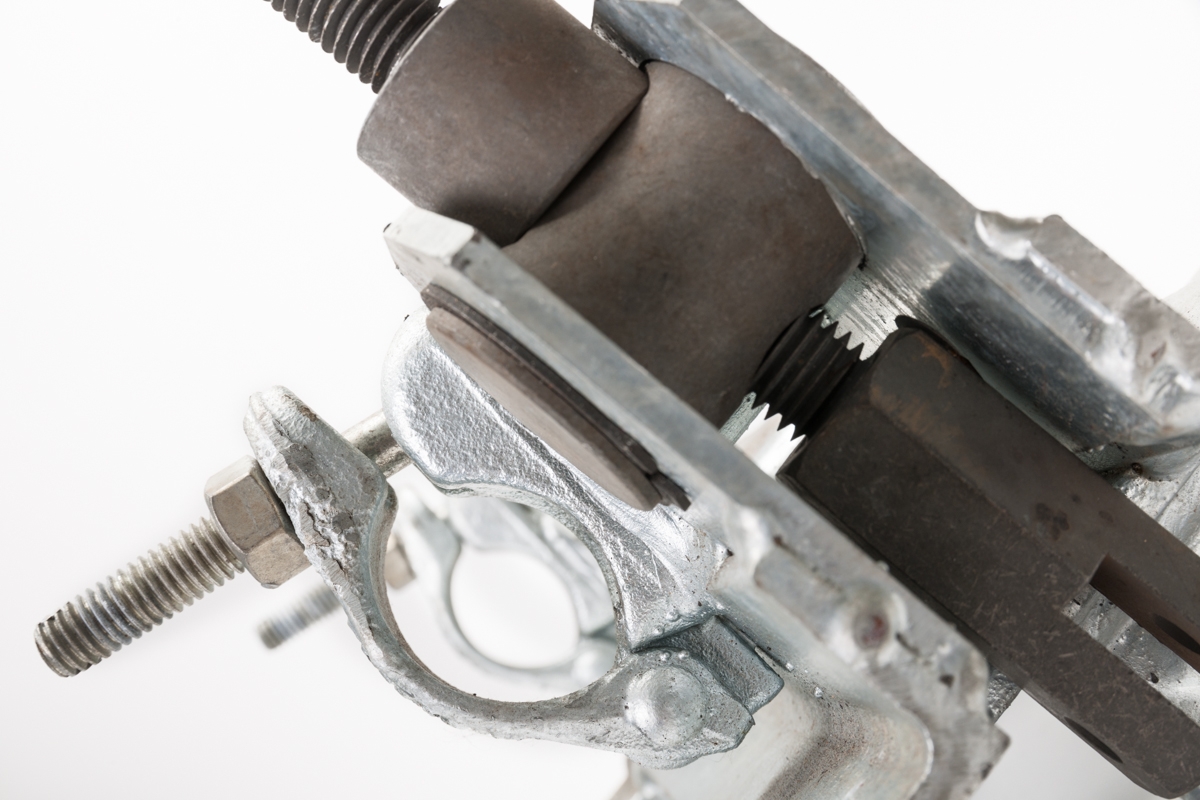

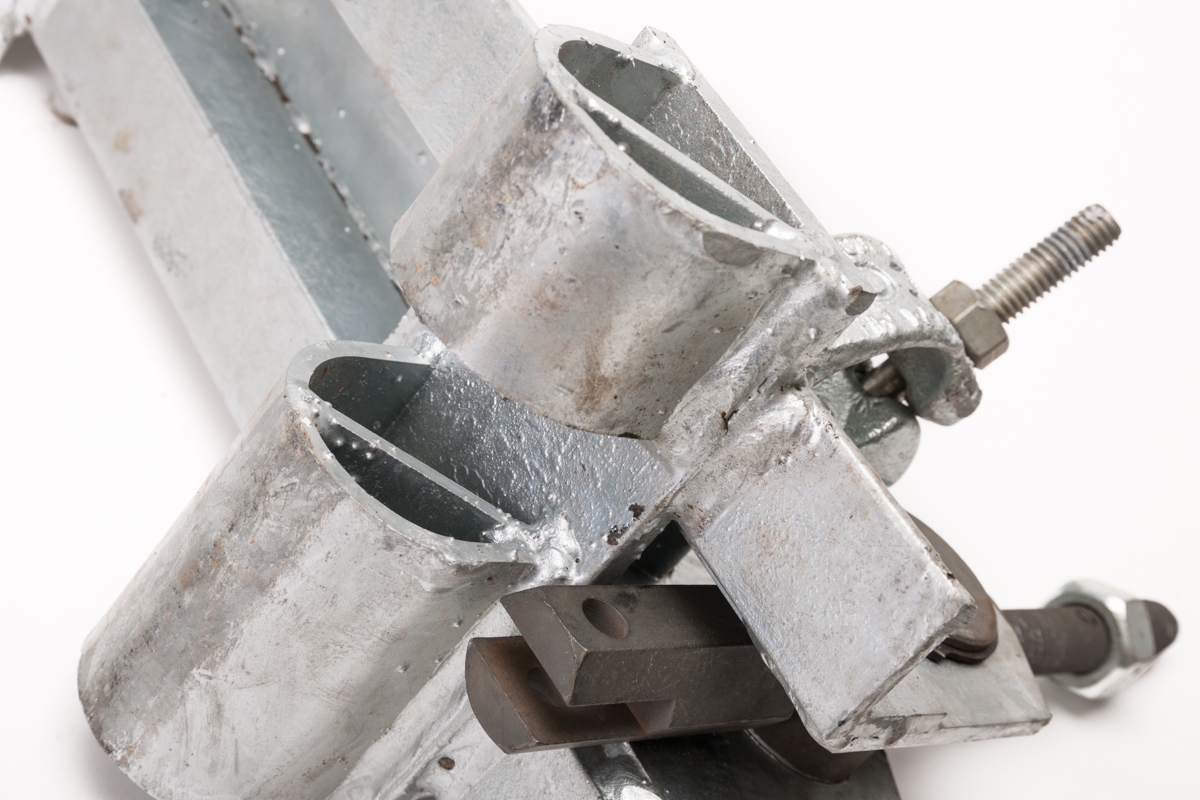

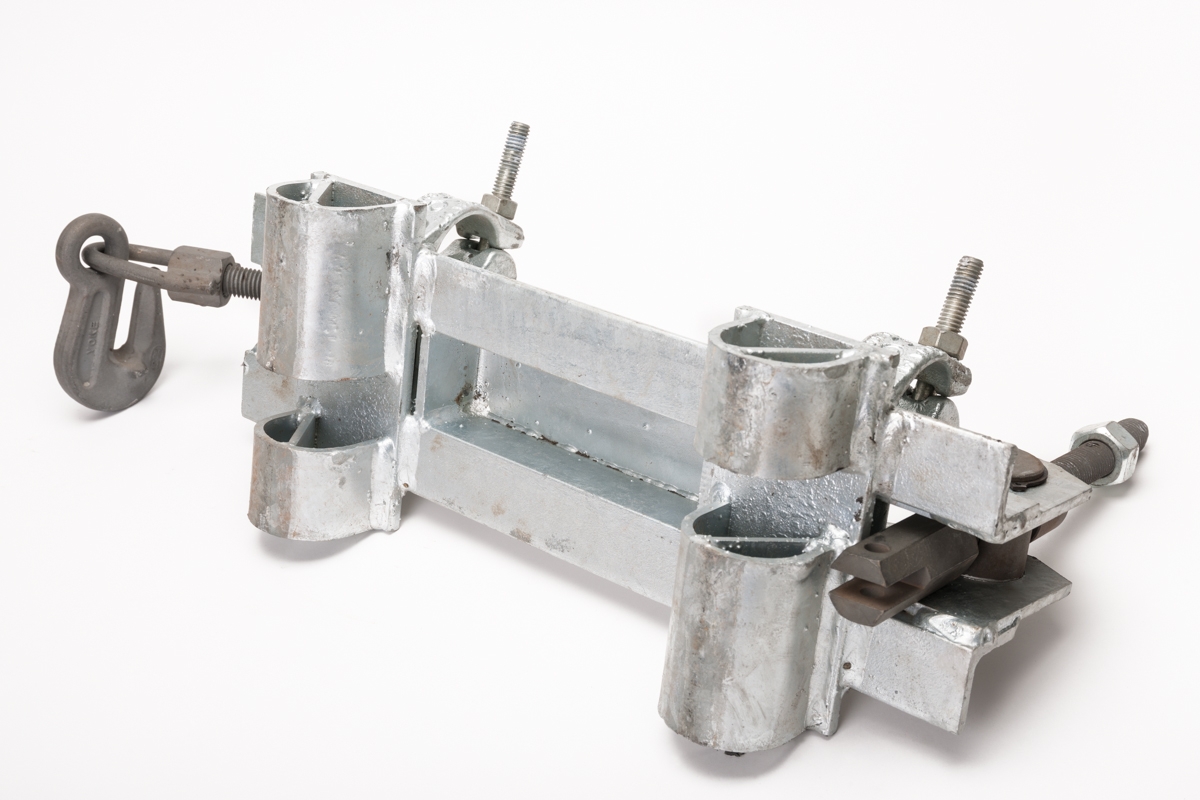

The Scaffolding Friction Clamp is used extensively offshore, here in the UK and Internationally. Used on tubular steel work it can be fitted to horizontal, inclined or vertical members of any diameter from 500mm upwards to enable Scaffold tube and structures to be built from them.

A specialist item within the industry, GR Friction clamps come with tested and certified chain to any length required for your projects.

Directions of use of the Friction Clamp

Although the friction clamp will have some resistance to loading applied parallel to the axis of the tubular member, it is intended to support loading applied at right angles to the axis.

The maximum permissible applied load and out of balance moment when applied as illustrated are 30KN and 4.5KN m respectively. The minimum length of chain required will depend on the diameter of the tubular member concerned.

Scaffolding Base Plate

Scaffolding Rubbish Chutes

Scaffolding Sleeve Coupler

EN74 Scaffolding Base Plate

Lay Flat Fitting

Klawz Scaffold Fitting

Ladder Access Gate

Universal BrickGuard

We proudly helped 11 inspiring charities in 2025.

Every single eligible product we provide has been approved by NASC.

Committed to Total Reliability of Supply, we are the leading independent scaffolding supplier in the UK and exporting worldwide.

No suggestions found.

No results found in products.

No results found in other sections.